Why Building with Steel ?

Watch the video below

STEEL VS. WOOD FRAMING

Cold-formed steel (CFS) is rapidly becoming the material of choice for low to mid-rise construction in Canada due to inherent advantages such as :

Waterproof - No more Structural Problems due to Leaks

Non-Combustable

Fast offsite and onsite fabrication (50% faster than wood)

High strength to weight ratio - Use of light foundations

Lightweight & ease of handling (40+% lighter than wood)

Cost-Effective

No Rotting, Warping or Cracking

Pest and mould resistance

Dimensionally constant and stable

LGSF is BIM design-led and accurate to half a millimetre

Easily fabricated to a wide range of custom profiles and sizes

Virtually no material waste (>2% compared to 15-20% for typical wood construction)

Long-term viability, as its material properties do not deteriorate over time

Seismic and Wind Resistance

Flood Resistant

LGSF construction is environmentally friendly

Most Recycled material in the world

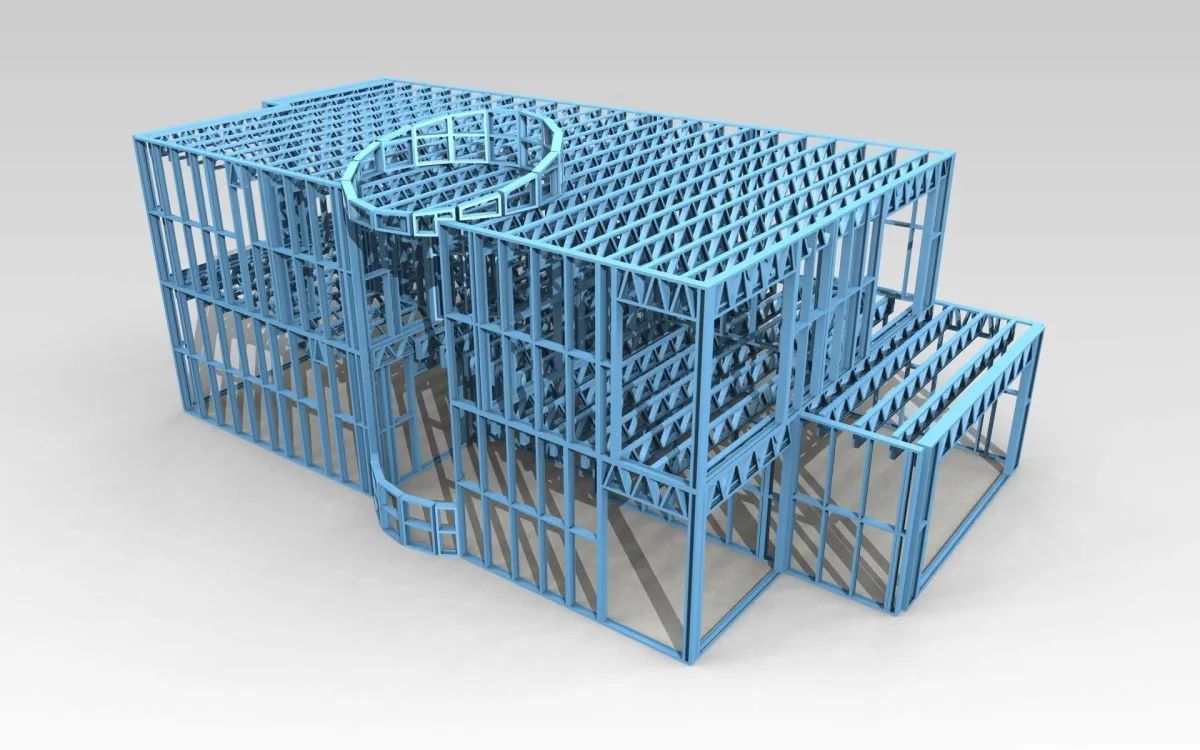

Light Gauge Steel Frame (LGSF) is a type of construction technology that makes use of cold-formed steel as the primary building material. It can be applied to roof systems, floor systems, wall systems, roof panels, decks, and the entire structure.

OUR FRAMING SOLUTIONS

Residential Framing Solutions for Developers and Private Home Builders

From single family homes to multiplexes (duplexes, triplexes, etc.), and townhouses to apartment buildings up to 3-4 stories high.

Frame Factory manufactures a turn-key steel frame structure per client design and installs the structure with exterior sheathing wall and roof panels on the client's site.

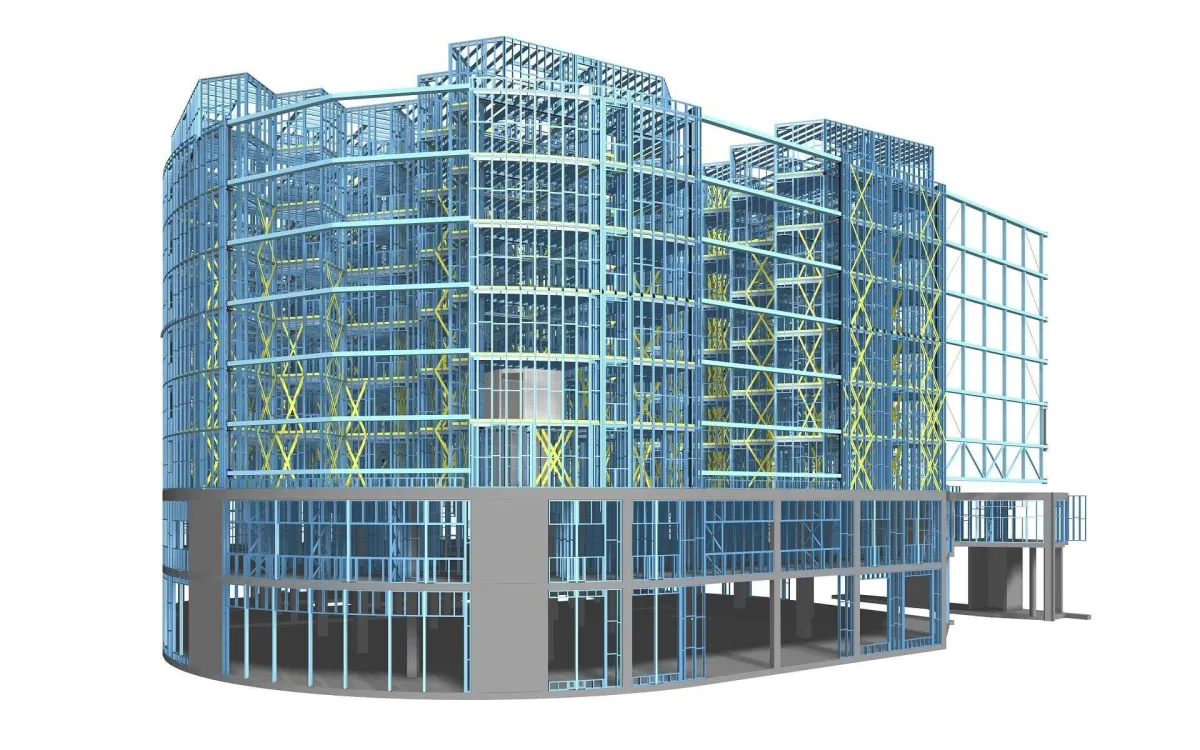

Commercial Framing Solutions for Builders, Property and Business Owners

From work shops and garages to retail plaza stores, from restaurants to office buildings up to 3-4 stories high.

Faster Production and frame Installation translates into faster Return on business investment.

Healthcare and Education

From Public and private Schools to Colleges and Student Dormitories, from Medical offices and private clinics to Hospital buildings up to 3-4 stories high.

Affordable Housing Solutions

Our light gauge steel technology offers an efficient and faster way to build affordable housing without sacrificing quality.

We work with our clients to design and build low-rise multi-unit residential buildings that meet their specific requirements, including accessibility features, energy efficiency, and non-combustable durable materials.

Hotels, Motels, Resorts and Hospitality

The Frame Factory hotel solutions provide many advantages over traditional building methods including reduced cost and material waste, faster structural design and prefabrication of panels and modules, which in turn translates into 50-100% faster construction.

Accessory Dwelling Units (ADUs)

Garden Suites

Our ADUs or garden suites allow homeowners to increase their living space without the expense and hassle of traditional construction materials.

Our steel panels and modules are designed and built to fit into existing backyards, providing additional housing / income options for homeowners.

Additions and Top-up Floors

The lightweight of steel frame enables the extra top floor or over-roof to be built without making as many changes to the existing foundation than would be necessary if heavier materials were used.

Not only are steel frame constructions lighter and more durable than wood, but they also speed up the building time.

FAQS

How much does the Steel Frame cost in comparison with traditional Wood Frame?

Frame Factory Steel Frame costs almost the same as traditional Wood Frame with superior advantages over Wood Frame such as up to mm accuracy, stability, production speed, non-flammable, light weight, and many more advantages.

Do you install the steel frame once you manufacture it ?

Yes, Frame Factory provides turn-key installation of its steel frame on client’s site. Please fill-out the request form on this site with your location and we will contact you momentarily.

Do you include installation of exterior sheathing panels ?

Yes, absolutely. We include installation of exterior sheathing wall and roof panels with choice of various materials such as DenseGlass, OSB, plywood and rigid foam.

How long does it take to produce and install Frame Factory steel frame?

Unlike traditional wood frame where wood frame is normally made on the site, Frame Factory manufactures all steel frame components per clients AutoCAD design and the BIM model and pre-assembles all components into panels and trusses in the indoor facility; therefore, saving a lot of time for the client and providing with highest standards of quality control. The panels and trusses are then shipped to the clients site and installed by professional crew.

For example, depending on the design and complexity, 2,000+ sq. ft. home can be installed on the site within just TWO weeks.

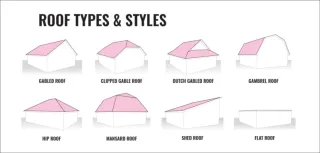

What roof types can you with ? Floor system ?

We can design and manufacture almost any type of roofs including pitched hip and gable roofs as well as flat and shed roofs. We manufacture our own floor and roof trusses.

Do you provide with stamped structural engineering drawings for your steel frame?

Yes, of course. Once the order is placed, we will provide with detailed structural design including 3D BIM model and stamped drawings by licensed engineer.

Is your steel corrosion free?

We use galvanized structural steel specifically formulated to protect steel against moisture

How can I get started ?

You can start by filling out short contact form. You can submit your architectural vision by attaching your pdf or AutoCAD file containing your design and requirements. We will provide with estimate along with 3D model. Once approved and order placed, we will provide with 3D BIM Model with stamped structural drawings for your submission.